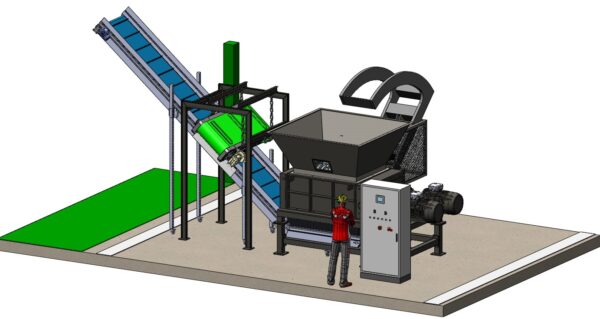

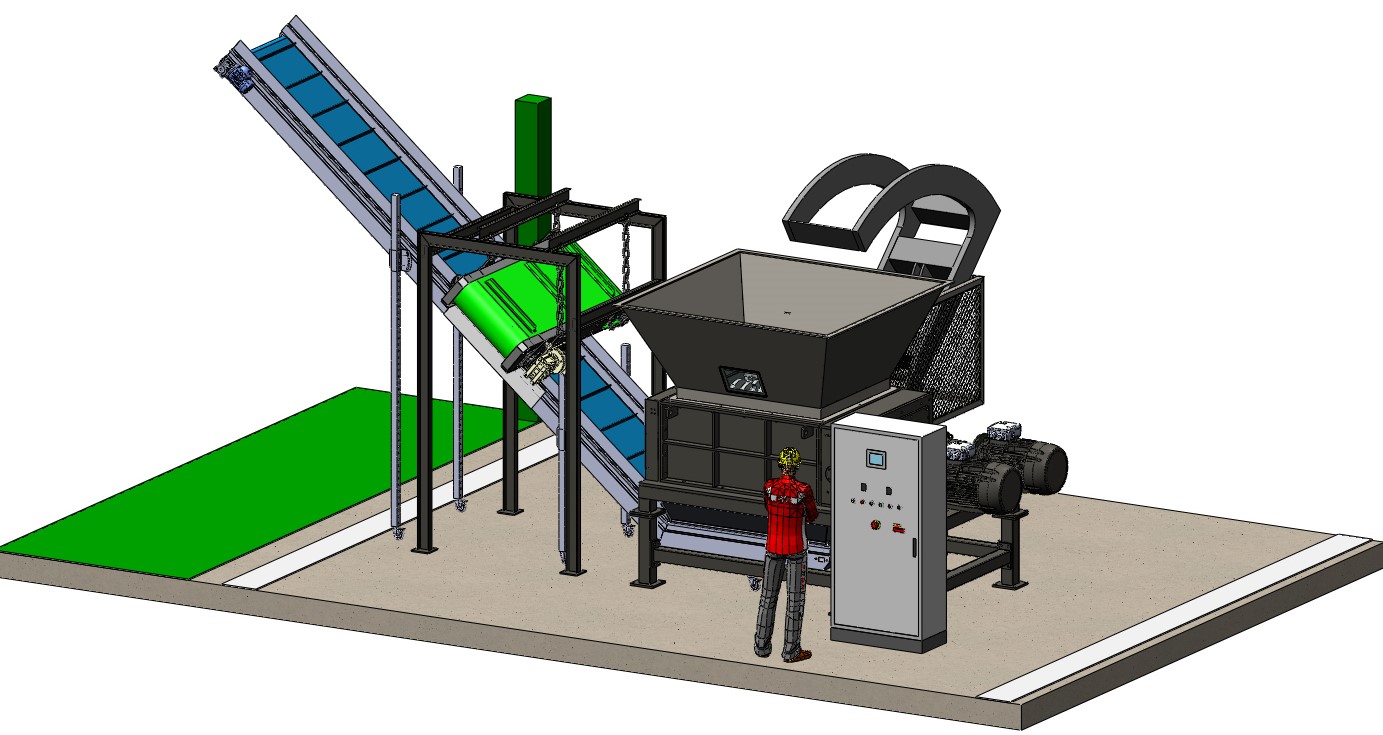

This is the tailor-made project we have created for our Hungarian customer who needed to shred IBC with metal cage. This particular system composed as follows has been studied to separate the plastic in the IBC and the metal cage after the shredding process!

This shredding line is composed by:

- N.1 SHREDDER MODEL TRITO 140/100S

Nr. 1 UNLOADING CONVEYOR BELT

- Nr. 1 OVERBAND IRON REMOVAL

Among our range of shredder, the 140-100S four-shaft shredder is a medium sized multipurpose machine suitable for shredding an enormous number of waste materials- even very large. It is usually recommended to process material as wood, pallets, rags, plastic, leather, tyres, paper, cardboard, packaging, polyethylene banding, plastic film, PET bottles, milk bottles, different types of containers, paper documents, plastic scraps, upholstery, bumpers, small trunks, tarpaulin, etc.

MAIN CHARACTERISTICS of the 140-100S shredder:

- Dimensions of the cutting chamber: 1000×1400 mm

- Installed power: 44 KW (22 kW+22 kW) – 60 HP (30 HP + 30 HP)

- Drive: by gears

- Number of cutting chamber: 2

- Number of knives: 35

- Number of upper shafts: 2

- Number of upper knives: 35

- Rotating speed (RPM): 18

- Capacity: 2-3,5 t/h

- Safety: emergency stop, safety switches for hopper and frame manufactured to EC standards